Introduction: The importance of access to critical minerals for the energy transition

Introduction: The importance of access to critical minerals for the energy transition

Achieving a sustainable energy transition that limits greenhouse gas emissions while promoting inclusive economic growth and development is crucial for addressing climate change yet remains a significant challenge. Green technologies such as solar panels, wind turbines, electric vehicles, and hydrogen fuel cells lie at the heart of this transition. These technologies, however, rely on specific metals and minerals—aluminium, cobalt, copper, lithium, nickel, and others—several of which remain hard to access for many countries, and are in limited supply. Demand for each mineral varies by each clean energy technology. In the case of batteries, that demand also varies according to battery type (e.g., lithium-ion batteries can have different compositions, such as lithium iron phosphate, lithium nickel cobalt aluminium, or lithium nickel manganese cobalt oxide).

A common feature of the supply chain of these important minerals is a high degree of geographical concentration of reserves, production, or refining. For instance, nickel is mined in Indonesia, the Philippines, and the Russian Federation, but its refining is largely done in China and Indonesia. China exports over 85 per cent of the world’s rare earth elements, while the Democratic Republic of the Congo (DRC) supplies approximately 70 per cent of global cobalt. Lithium is primarily sourced from brine deposits in Argentina, Bolivia and Chile, while Australia leads in hard-rock lithium mining (IEA, 2024a).

This geographic concentration of supply chains is associated with economies of scale, which—while reducing production costs—also creates bottlenecks that can be a source of strategic advantages for certain countries. Such concentration also creates risks of supply disruptions, geopolitical dependencies, and market volatility. Additionally, the extraction and processing of these minerals can have profound environmental impacts, including habitat destruction, water pollution, and greenhouse gas emissions, exacerbating ecological challenges even as these minerals are used to combat climate change. For countries without domestic processing capabilities or sufficient reserves, the combination of rising demand, along with potentially fragile supply chains has led to several of these minerals being designated as “critical”.

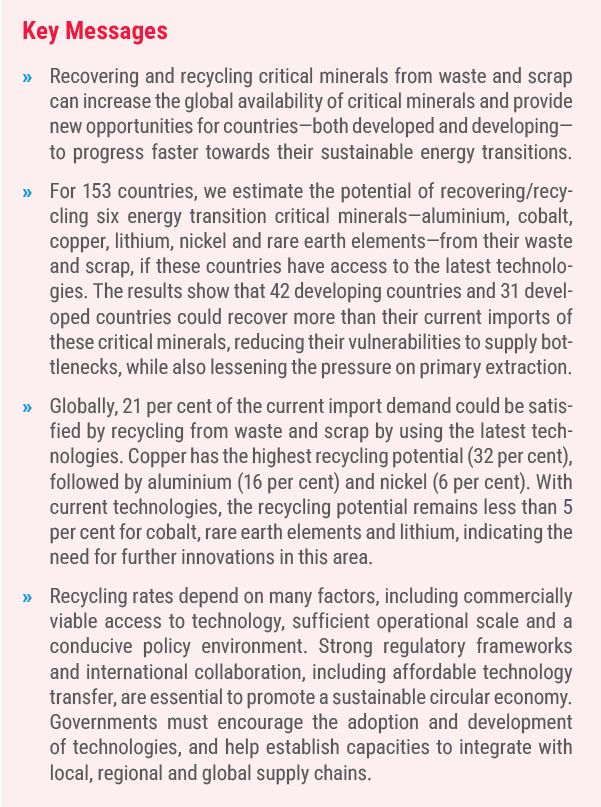

Several countries are uniquely positioned to benefit from the global demand for critical minerals. As shown in Table 1, countries such as Australia, Chile, the DRC and Indonesia hold substantial reserves of nickel, lithium, and cobalt, collectively accounting for over 80 per cent of global reserves for certain minerals.

Given the geographically concentrated production and supply of several critical minerals, recycling from waste and scrap can be a significant way for many countries, including developing countries, to reduce reliance on primary sources. Recycling also promises to augment the total supply of minerals that are important for the energy transition, helping to secure availability and avoid disruptions in progress towards important sustainability goals.

Access to critical minerals can also underpin a broader economic transformation. These resources offer a pathway for developing countries to attract foreign investment with strong domestic linkages and spillovers, generate significant revenues, and foster industrialization. By leveraging their mineral wealth, these nations can diversify their economies, reduce reliance on traditional sectors like agriculture or fossil fuels, and strengthen their global competitiveness.

Processing critical minerals within these countries enables the creation of skilled jobs, the development of infrastructure, and the establishment of domestic supply chains that are less vulnerable to global disruptions. For instance, setting up facilities for refining rare earth elements or manufacturing lithium-ion batteries locally can ensure that these countries benefit from higher-value stages of the supply chain. This approach supports long-term economic resilience and equips local workforces with expertise in high-demand industries.

Recycling and recovering these materials from end-of-life products, such as batteries and electronic waste, present significant environmental and economic benefits, but also come with challenges. Recycling reduces the need for new mining, minimizing the ecological impact of habitat destruction, water pollution, and greenhouse gas emissions. For instance, aluminium, copper, and cobalt can achieve recycling rates of nearly 100 per cent with existing technologies. However, recycling rates for minerals like lithium and rare earth elements remain below 1 per cent, particularly in developing regions due to technological and economic barriers. At the same time the waste and scrap necessary for recycling is more likely to be produced in countries that are further along their energy transition, and recycling in developing countries requires access to this supply stream. While developing countries import these critical minerals and also generate waste and scrap, the latter are often exported due to lack of investments in advanced recycling infrastructure. Such investments can enable countries to recover valuable materials from domestic and international waste streams and reduce dependence on imports of newly mined minerals.

Moreover, recycling can serve as an engine for innovation and job creation. Advanced recycling processes, such as hydrometallurgy and bioleaching, not only recover valuable materials but also generate demand for skilled labour and technical expertise. In India, for example, private and public efforts aim to expand local recycling industries. However, public support is often necessary. For instance, the Government of India has implemented the Plastic Waste Management Rules and the Extended Producer Responsibility mandates to curtail electronic waste and to promote investment in the recycling industry. In addition, its Waste to Wealth Mission explores innovative solutions to the country’s waste and landfill challenges (Office of the Principal Scientific Adviser to the Government of India, 2025). These and other efforts demonstrate how developing nations can innovate within their local context and constraints. Establishing robust recycling systems not only supports economic growth but also contributes to achieving the Sustainable Development Goals (SDGs).

As the global transition to clean energy accelerates, the role of critical minerals will only grow in importance, and developing countries will increasingly adopt green energy technologies. These countries, with their increasing technical and institutional capacities, can further leapfrog towards sustainability through access to recycling technologies and advanced recycling infrastructure. By adopting circular economy practices, investing in—and fostering—local industries, recycling from waste and scrap of critical minerals can reduce their environmental impact, diversify their economies, and ensure their energy transitions are both sustainable and inclusive.

This Frontier Technology Issue estimates the potential of 153 countries to use recycling of waste and scrap for reducing the need for mining while meeting their domestic demand for identified critical minerals including copper, aluminium, cobalt, nickel, rare earth elements and lithium. It arrives at the global estimates on how global demand for these critical minerals can be partially met by recycling from waste and scrap, closing the supply loop in each country. It identifies the challenges for developing countries in creating a closed-loop supply chain and identifies some of the technologies which are being used by (mainly advanced) countries to recover, recycle and reuse. The Issue proposes targeted policies, strategic interventions and shares successful national policies and regulatory frameworks which can support recycling of critical minerals from waste and scrap. It recommends actions at national, regional and global levels which can help countries to technologically advance and progress on their SDGs by using closed-loop supply chains.

The growing trade in waste and scrap of critical minerals

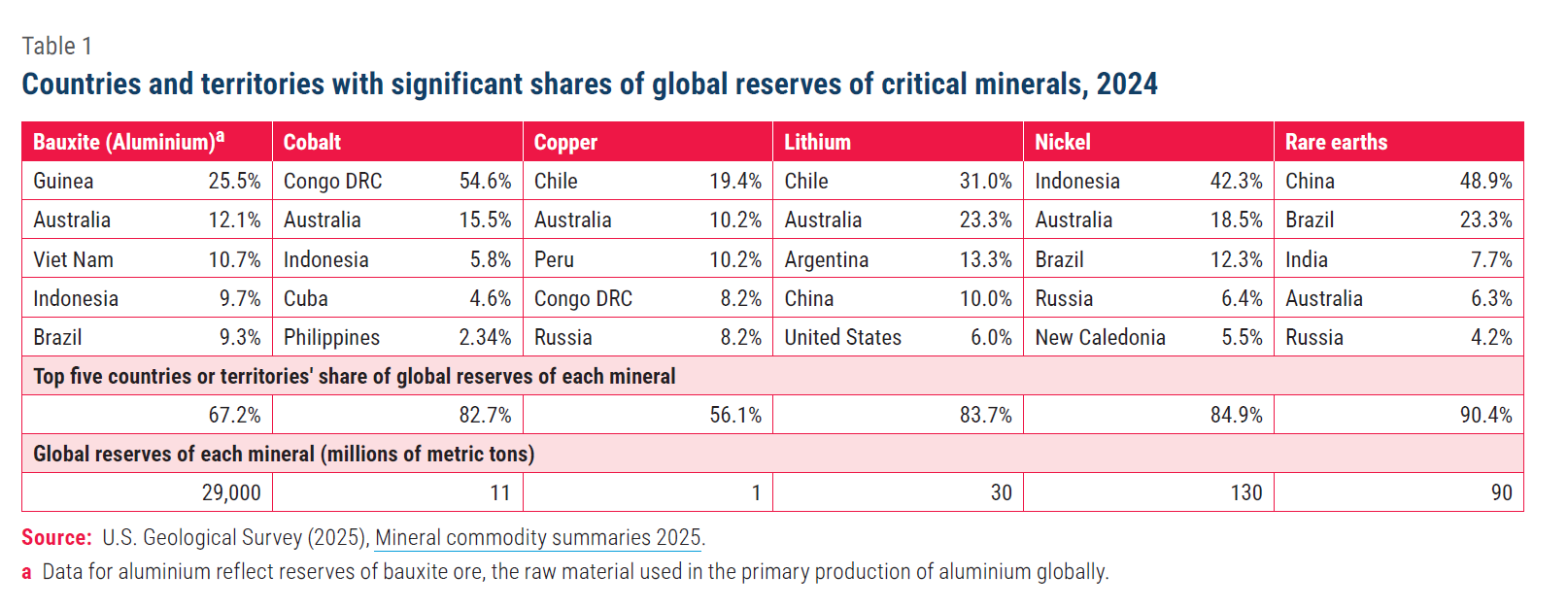

The trade in waste and scrap of critical minerals has been experiencing notable growth in recent years, driven by increasing demand for these materials by scrap buyers and the rising need for sustainable recycling practices. Trends in global imports of waste and scraps of identified critical minerals show a clear upward trajectory, as countries look to supplement their domestic production with recycled materials. Figure 1 highlights the growing global demand for waste and scrap of aluminium, lithium, copper, rare earths, nickel and cobalt since 2007.

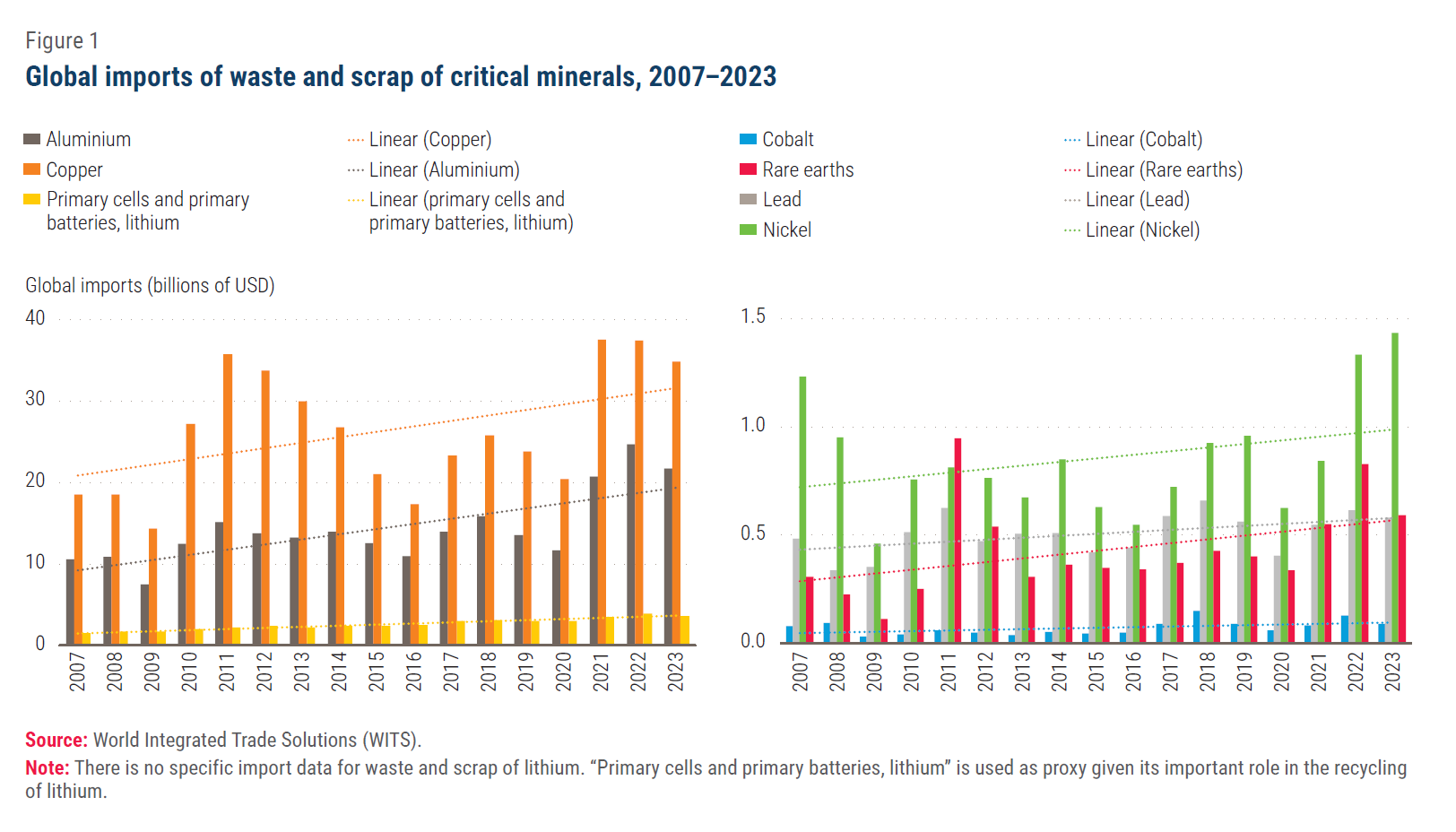

Major participants in the trade in waste and scrap include both developed and emerging economies, with countries like China, Germany, India, Japan and the United States playing significant roles (Table 2). These nations possess advanced recycling technologies and infrastructure that allow them to capitalize on the growing market.

However, exports of waste and scrap remain common even from countries with advanced technological capabilities. This trade occurs for a variety of economic and structural reasons and patterns are shaped by capacity constraints and by the relative profitability of exporting to countries with lower processing costs and potentially fewer regulatory hurdles. In many cases, recycling is not economically viable due to high energy costs, limited installed capacity, or highly specialized recycling lines that cannot efficiently handle mixed or low-grade materials. For example, the United States has a significant processing capacity gap, with domestic facilities able to handle only 25 per cent of the recyclable material available. As a result, the United States remains the world’s largest net exporter of copper scrap, exporting around 0.8 million metric tons in 2022—60 per cent of which went to Asia, and half of that to China (IEA, 2024a, 2024b).

Even in Europe, where environmental policies strongly support circular economy practices, institutional barriers can discourage domestic recycling. The classification of scrap as “waste” introduces compliance obligations that increase costs and complexity for recyclers. Volatile electricity prices and thin profit margins in the recycling sector have further constrained domestic investments, especially in pre-processing and upgrading infrastructure. While aluminium and copper recycling are relatively established, the recycling of many energy transition minerals—including lithium, cobalt, and rare earth elements—remains nascent, with limited economic incentives to expand capacity. According to the International Energy Agency (IEA), the share of secondary copper supply has remained largely unchanged since 2015 (IEA, 2024b). Rather than reflecting a failure to recycle, these exports highlight the global nature of supply chains and the need for targeted investments to increase domestic recycling efficiency and competitiveness.

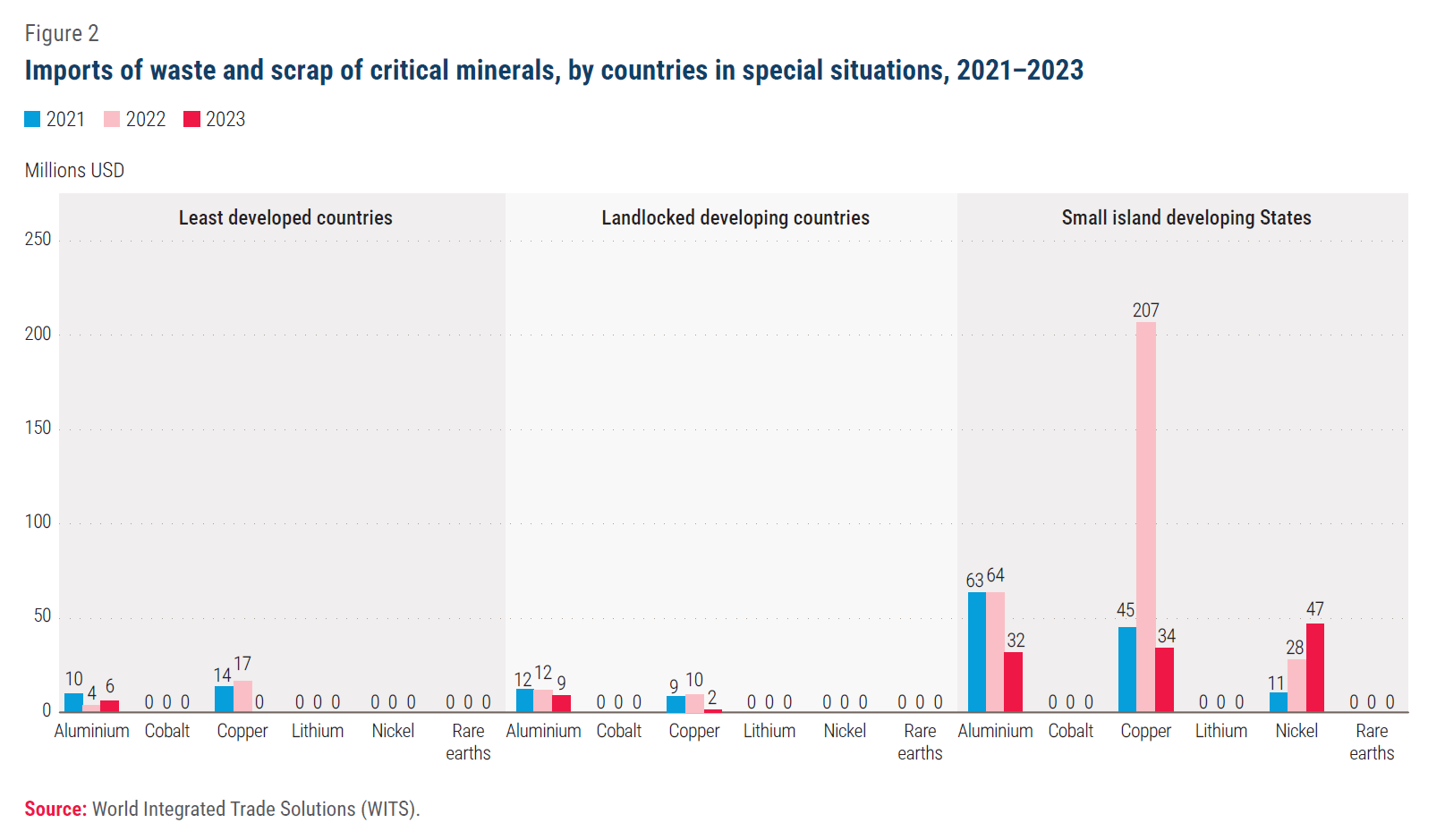

Consequently, the trade in waste and scrap is expanding even in smaller and poorer countries, though at a much slower pace (figure 2). While these nations face challenges such as limited access to recycling technologies, financing, and technical expertise, the potential for growth remains substantial. However, apart from technological capacities to recover and recycle critical minerals from their waste and scrap, countries require strong waste management infrastructure to dispose of the waste and scrap post-recovery and recycling. As the global recycling industry continues to evolve, supporting the development of recycling infrastructure and waste management practices in these countries could unlock opportunities for both economic growth and environmental sustainability.

While increased recycling will contribute towards meeting the total requirement of critical minerals now and in the future, this need not lead to a decline in the demand for critical minerals from exporting countries. As countries seek to accelerate their energy transitions, global demand for critical minerals is expected to accelerate beyond what is available through recycling. Moreover, countries are also aiming to digitally transform their economies, and digital technologies are an additional source of demand for the critical minerals discussed in this Issue.

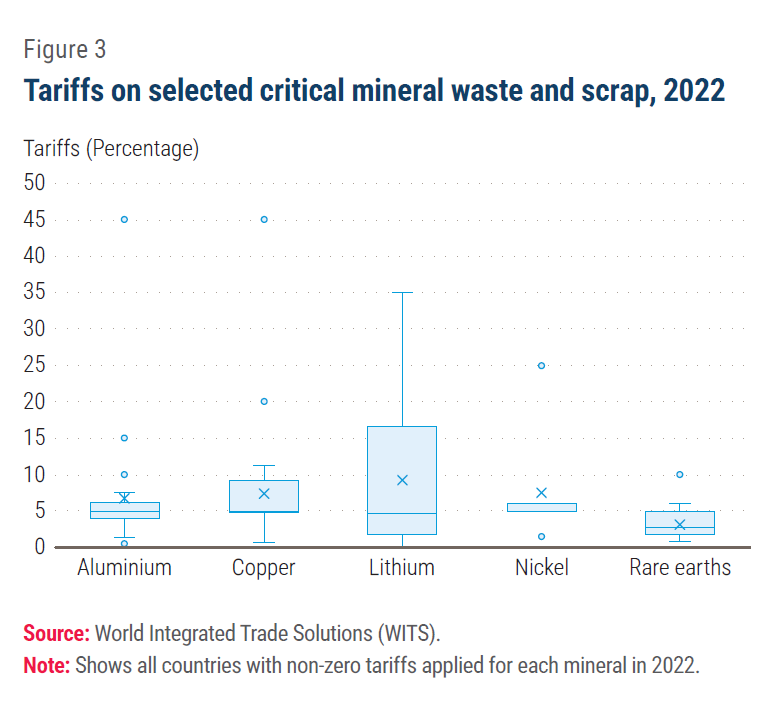

In recent years, several developing countries (for example, Angola, the Bahamas, Bahrain and Bermuda) have started imposing tariffs on the imports of waste and scrap containing critical minerals, at least partly to protect their local environment and reduce the environmental impact of processing these materials. Figure 3 shows that while most of these tariffs are below 10 per cent, some countries have much higher rates ranging from 15 to 45 per cent.

Tariffs are often introduced to ensure that imported waste does not overwhelm local recycling systems, which may lack the capacity to handle large volumes of scrap, leading to improper disposal and pollution. In most developing countries, however, these tariffs are less than 5 per cent so their deterrent effect is not clear. Balancing environmental protection with the need for a sustainable supply of critical minerals remains a complex issue for developing nations. Imports of waste and scrap need to be regulated based on the existing waste management ecosystem since after the critical minerals are recovered from their waste and scrap, disposing of the rest can become an onerous task if a country does not have a robust waste management system.

Potential of recycling critical minerals from waste and scrap in developing countries

At present, the world consumes nearly 100 billion metric tons of materials annually. Material consumption has tripled since 1970 and is expected to double again by 2050, intensifying pressure on ecosystems and natural resources. This trajectory underscores the imperative to shift towards circular economy models, where resources are reused, recycled, and kept in circulation.

Without a significant push to increase the circularity of our resources, material consumption will continue to deplete natural resources, drive biodiversity loss, and contribute to climate change. The implementation of circular strategies is even more urgent due to the growing demand for critical minerals essential for modern technologies and the global green transition.

Current rates of recycling of critical minerals

Current rates of recycling of critical minerals

Recycling is vital in reducing dependence on primary resource extraction. Recent data estimates that only 7.2 per cent of material extraction is cycled back through recycling and reuse. This share is down from 9.1 per cent in 2018. According to some estimates, with existing infrastructure and technologies recycling could meet only 20 per cent of the total mineral demand between now and 2050 (Simas, Aponte and Wiebe, 2022). However, part of this limited impact stems from the still accelerating pace of the energy transition. Recycling rates should respond to rising demand and higher prices for the minerals, as well as innovations that drive down recycling costs.

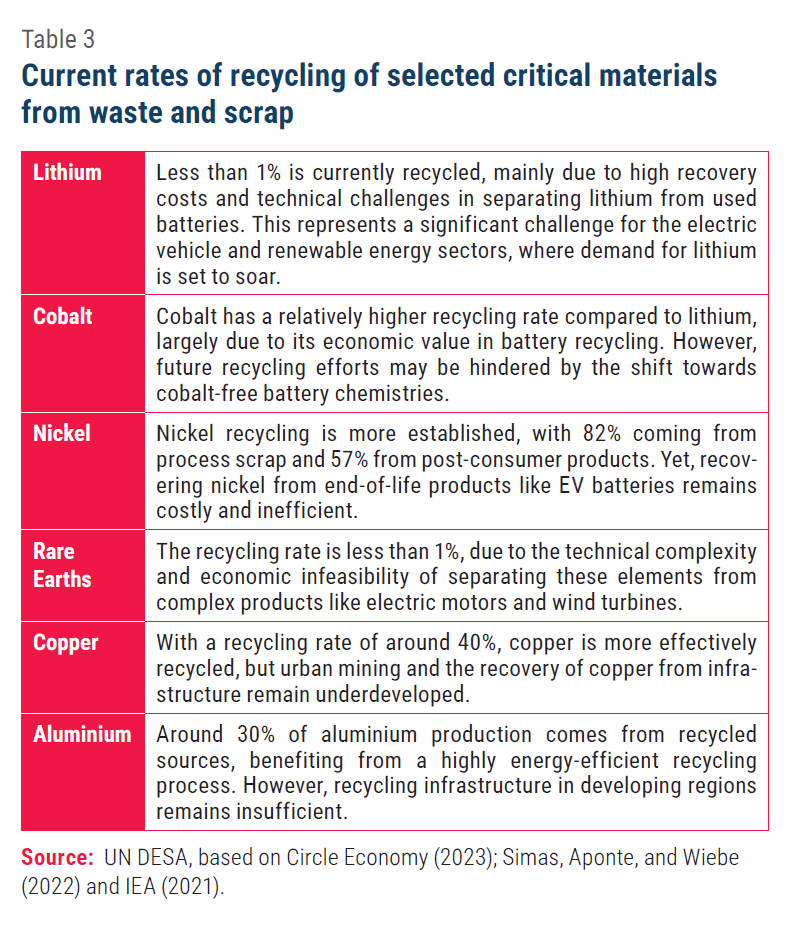

Table 3 reports the current rates of recycling of identified critical minerals from waste and scrap. The rates are currently low, which highlights the potential for investments and regulatory reforms that can enable the transformative change necessary for more sustainable practices. Additionally, the impact of recycling will only start to be felt significantly after 2040, as many of the low-carbon technologies currently being deployed (such as electric vehicles and renewable energy systems) reach their end of life, and recycling of these materials can start.

Estimating the recycling potential from waste and scrap

We estimate the potential of recovering/recycling six identified critical minerals from their waste and scrap for 153 countries. This is done by first estimating the total availability of traded waste and scrap of these critical minerals in each country by using total exports and imports of waste and scrap of the identified critical mineral in each country, (using three-year averages of 2021–2023). The rates of recovering critical minerals from their waste and scrap using the latest technology are then applied to the total availability of waste and scrap in each country to arrive at each country’s maximum potential gains from recycling. These gains, expressed as a proportion of imports of that critical mineral, indicate the extent to which the country can meet its current demand through recycling, reducing the need for imports or local mining.

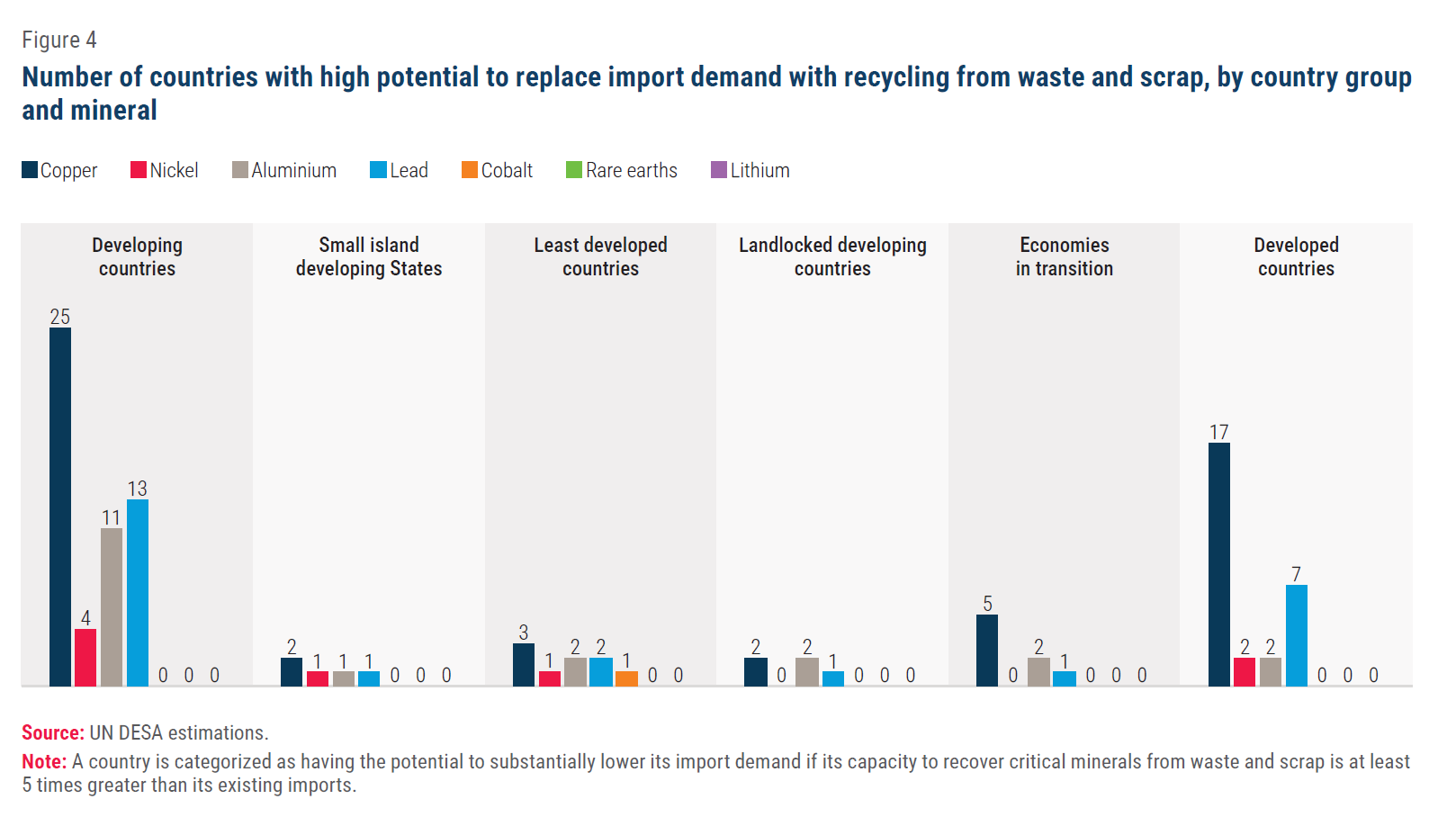

Our analysis shows that recycling from waste and scrap can significantly increase the availability of critical minerals and reduce current import demand for critical minerals in more than 80 developing countries (figure 4). In developing countries, the potential to recycle is highest for copper followed by aluminium, rare earth elements and nickel. There are 35 developing countries (including 5 small island developing States) which have the potential to recycle and recover more than their current imports of rare earths. However, many countries, especially those in special situations, may require additional support in terms of technology, funding, and technical capacity and skilled personnel to fully realize their recycling potential. An additional benefit of reduced import demand is the conservation of critical foreign exchange reserves.

At the global level, it is estimated that around 21 per cent of global import demand can be satisfied by recycling from waste and scrap in the six identified critical minerals, with the potential being highest for copper (32 per cent), followed by aluminium (16 per cent) and nickel (6 per cent). The potential of recycling from waste and scrap remains less than 5 per cent for cobalt, rare earths and lithium, indicating the need to invest in technological advances in recovering these minerals (IEA, 2024b).

The appendix provides estimates for 153 countries—both developed and developing—on the extent to which their current import demand for six critical minerals can be lowered by recycling currently available waste and scrap.

Table 4 reports the top five countries with the highest potential to meet their current need for critical minerals from waste and scrap presently available to them from trade. Countries such as Nicaragua, Madagascar, Paraguay, India, Brunei Darussalam and Estonia have the highest potential to recycle aluminium, cobalt, copper, lithium, nickel and rare earth elements, respectively.

Challenges in establishing a closed-loop supply chain in developing countries

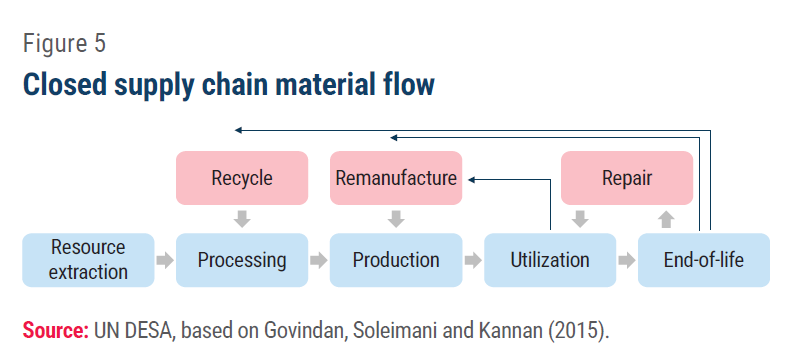

Realizing the promise of recycling requires countries to establish closed-loop supply chains (CLSCs). Unlike traditional linear supply chains, the CLSCs integrate waste back into the production cycle, transforming it into valuable inputs (figure 5).

Realizing the promise of recycling requires countries to establish closed-loop supply chains (CLSCs). Unlike traditional linear supply chains, the CLSCs integrate waste back into the production cycle, transforming it into valuable inputs (figure 5).

The circular economy offers not only environmental benefits but also economic opportunities. Enhancing recycling infrastructure including waste management, improving resource management, and adopting advanced technologies can help these countries reduce reliance on primary extraction while creating new jobs and fostering innovation. For example, scaling up urban mining to recover copper and other valuable metals from discarded electronics and infrastructure presents a significant opportunity.

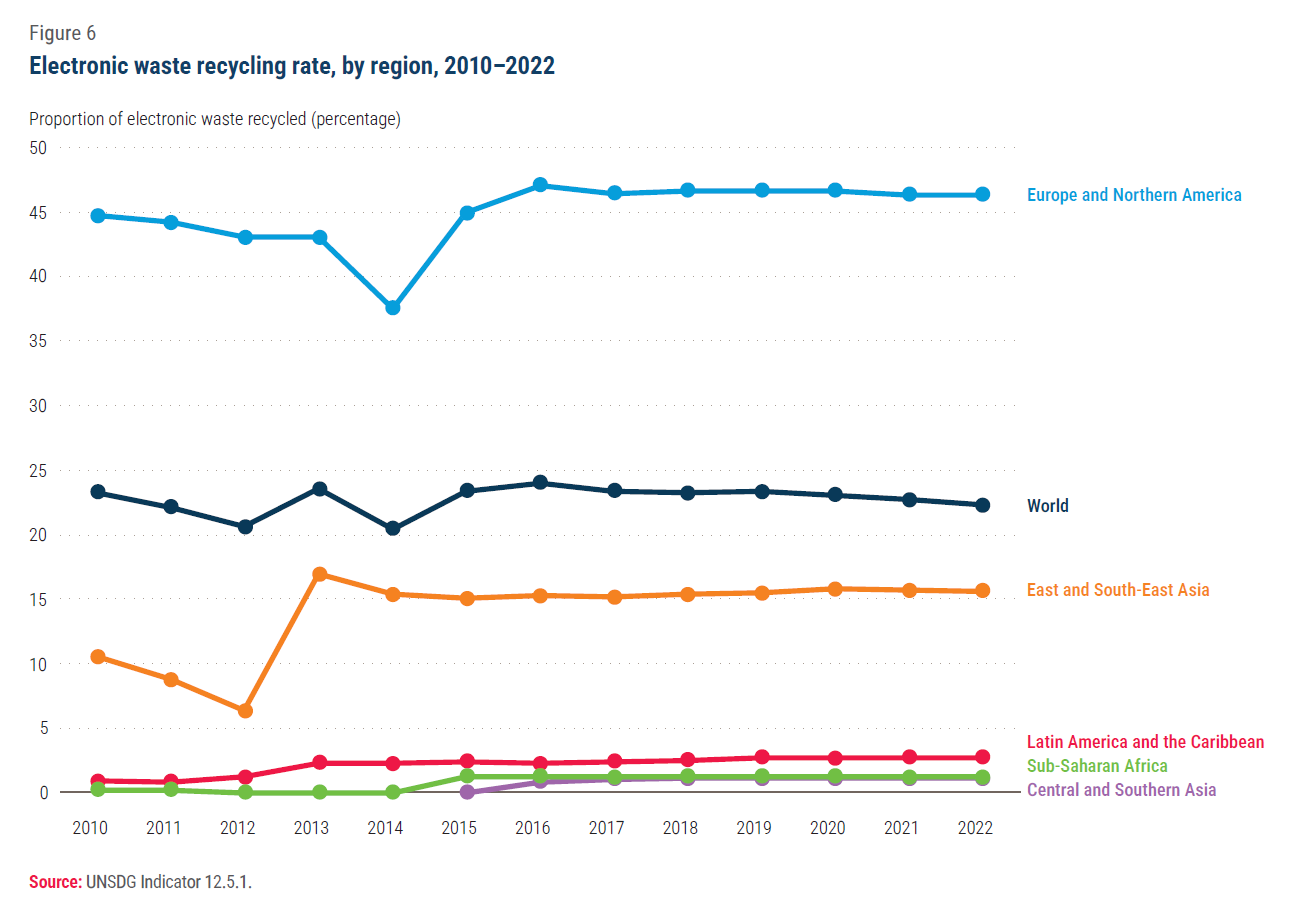

But developing countries face substantial challenges in recycling from waste and scrap and establishing CLSCs, despite their immense potential to promote sustainability and economic growth. For instance, in the electronics industry, the recycling rate of e-waste in regions like Europe and North America is nearly 50 per cent (figure 6). In contrast, recycling rates in Latin America, the Caribbean, sub-Saharan Africa, and Central Asia remain below 3 per cent. This stark disparity is driven by several factors, including the ability and economic viability of capturing the e-waste for recycling, the availability of recycling facilities capable of processing the various materials, and the economic case for selling the recycled product. This variability highlights the technical, economic, and systemic limitations that collectively hinder the implementation of CLSCs in developing regions. Such considerations are also relevant for the recycling of critical energy transition minerals.

To support a circular economy, developing countries can leverage recycling technologies that have proven effective in case studies from around the world. Technologies such as hydrometallurgy, pyrometallurgy, bioleaching, and direct recycling have shown success in recovering critical materials from electronic waste, batteries, and other end-of-life products. Each of these approaches offers unique benefits and can be tailored to fit the resource constraints and specific needs of different regions (IEA, 2024b; Institute for European Studies, 2019).

- Hydrometallurgy is particularly promising for developing nations due to its relatively low energy requirements compared to pyrometallurgy. This chemical-based process is already used in some regions, such as parts of Africa and Asia, to recover metals like cobalt and copper from mining waste. Its applicability to recycle e-waste and batteries is growing, although scalability and access to the necessary chemicals remain challenging. With targeted investments and training, hydrometallurgy could enable countries to recover valuable materials locally, reducing reliance on primary resource extraction.

- Pyrometallurgy, which relies on high-temperature smelting, is effective for recycling bulk metals like aluminium and copper. In countries such as Zambia, pyrometallurgical methods are already integrated into industrial processes. However, the energy-intensive nature of this technology makes it less viable for regions with unstable energy supplies or high electricity costs. Modernizing existing facilities with energy recovery systems could enhance the environmental and economic sustainability of pyrometallurgy in developing countries.

- Bioleaching presents a highly accessible and environmentally friendly solution for metal recovery. By employing bacteria to extract metals like copper, nickel, and gold from e-waste or low-grade ore, bioleaching offers a low-cost, low-energy alternative to traditional methods. This technology has already shown success in countries like Chile and Peru for mining applications and holds potential for adaptation in small-scale or informal recycling sectors in other developing regions. With proper training and microbial solutions, bioleaching could be a game-changer for rural communities lacking advanced infrastructure.

- Direct recycling focuses on reconditioning intact components, such as battery cathodes, without chemical or physical disassembly. While this technology is still in its infancy in developing countries, pilot projects in Asia demonstrate its potential. Simplified direct recycling methods could significantly reduce costs and energy consumption, making it a viable option for regions experiencing rapid growth in EV battery waste.

- Modular recycling units have proven especially valuable in areas lacking centralized recycling facilities. These decentralized systems can process local waste streams, reducing transport costs and emissions. Ghana provides a successful example, where modular units have been deployed to manage e-waste and recover materials like copper and aluminium. By supporting community-based recycling, modular units can create local jobs and increase material recovery rates in underserved areas.

- Low-temperature recovery techniques, such as cryogenic milling and solvent-based separation, are underutilized in developing countries due to technical and cost barriers. However, these methods are highly effective for recovering delicate materials like rare earth elements and battery components, preserving material quality while conserving energy. Adapting these technologies for affordability could enhance their application in regions with growing demand for such materials.

- Advanced sorting technologies, including x-ray fluorescence and near-infrared spectroscopy, are critical for improving the efficiency and purity of recycling. Currently, these systems are rarely used in developing countries due to their high cost and need for technical expertise. Simplified and affordable sorting tools could significantly improve material separation and recovery, particularly for e-waste streams that contain mixed materials.

Infrastructure and manufacturing challenges

Experience with the circular economy indicates that success is contingent on recognizing that countries require tailored solutions reflecting their specific constraints and opportunities. Developing countries may need to focus on building basic infrastructure for waste collection, sorting, and recycling, as well as addressing the challenges posed by the informal sector. The key challenges for developing countries are the need for better collection systems, technological innovations to improve recycling rates and strong infrastructure and policies for waste management. Currently, the collection rates for many critical minerals are low, especially in developing countries where infrastructure is limited. For example, for lithium, there is lack of organized systems for recovering used EV batteries, particularly in developing regions; for nickel and cobalt, their collection from post-consumer products remains weak globally; and for rare earth elements, the collection of products containing these elements is minimal, as many devices (such as smartphones and wind turbines) are not designed for easy disassembly.

Economic considerations pose another major challenge for CLSC adoption, such as the uncertainties of investment, the high upfront cost and volatile markets. The inherent uncertainties of CLSCs, such as the unpredictable returns on investment, deter the business from adopting CLSCs. The setting up of recycling and remanufacturing facilities requires significant capital investment, which is often out of reach for developing countries. The price of critical minerals, such as lithium and cobalt, are highly volatile, making it difficult to invest confidently in recycling infrastructure.

Recycling technologies supporting the CLSCs need to be cost-effective and environmentally friendly. One of the primary barriers to adopting CLSCs in developing countries is the lack of access to advanced recycling and recovery technologies. According to IEA’s analysis through European Patent Portal, the majority of patents and innovations in recycling technologies are concentrated in a few countries (IEA, 2024b), creating an unequal distribution of knowledge and resources. Existing technologies transfer initiatives fail to deliver the desired outcomes.

Patents and intellectual property related to recycling technologies

Intellectual property protections are essential for the development of recycling technologies, for example for lithium-ion batteries and electronic waste, but can also limit their wider availability. Patents have spurred innovation in advanced methods like hydrometallurgy, pyrometallurgy, and direct recycling—from 2014 to 2021, general global patent activity had an average growth rate of 4 per cent, whereas patent activity in the field of battery recycling increased by an average annual growth rate of 21 per cent (Dent, 2024).

Countries like China, France and Japan dominate patent activity, with China accounting for approximately 74 per cent of global filings in battery recycling. These patents often cover energy-efficient recovery methods for valuable materials such as lithium and cobalt, underscoring their importance in addressing the global energy transition.

Licensing fees for patented technologies, such as bioleaching methods reliant on specialized microbial strains, are often expensive and can constitute a formidable barrier to their use in many developing countries. This, combined with the lack of necessary infrastructure and expertise, hampers the ability of resource-constrained nations to adopt these innovations. The limited accessibility and affordability of appropriate technologies restrict recycling capacity in many countries, lowering the global rate of recycling of critical minerals. Given the positive externalities associated with the widespread use of such technologies, a case can be made for multilateral support to ameliorate the barriers to their adoption.

Improving access to technologies which can unlock the potential of recycling in developing countries

Collaborative frameworks and technology transfer initiatives offer potential pathways to address these barriers. Policies like the European Union’s Critical Raw Materials Act promote global cooperation and encourage patent holders to offer affordable licensing arrangements, particularly to nations participating in international sustainability efforts. Programs like India’s government-backed initiatives demonstrate the potential of local research centers to adapt existing patented solutions to regional contexts, creating cost-effective methods for recycling critical materials.

Open-source approaches provide an alternative route for broadening access to recycling technologies. Modular recycling units, developed and shared as non-proprietary designs, allow countries to customize systems for local applications at reduced costs. By embracing open-access models, developing nations can bypass high licensing fees and implement scalable solutions tailored to their needs. Initiatives such as the Basel Convention, which emphasize international cooperation in managing e-waste, could further encourage the sharing of critical recycling technologies as public goods.

Revisiting the TRIPS agreement at the World Trade Organization (WTO) is essential to facilitate the transfer of green technologies, including those for recycling critical minerals. Expanding TRIPS flexibilities, such as time-limited patents for identified green technologies, can accelerate access for developing countries. Lessons from the Doha Ministerial Declaration on the TRIPS Agreement and Public Health illustrate how such flexibilities can balance innovation incentives with equitable technology distribution (WTO, 2001). Such action will be key to enabling developing nations to contribute to a global circular economy, reduce reliance on primary extraction, and tackle climate change.

Existing national policies to encourage recycling from waste and scrap and closing the supply chain loop.

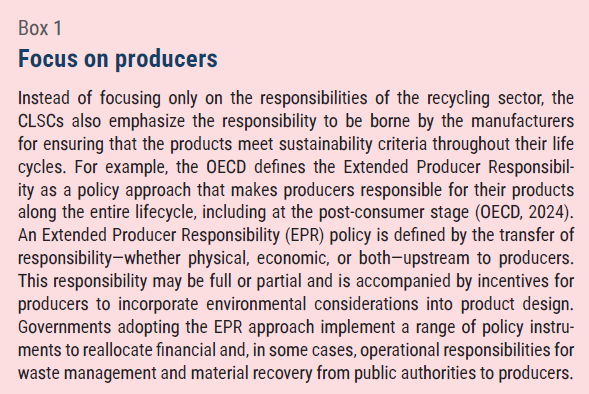

Governments can play a critical role in the promotion of recycling strategies among supply chain members through taxation, subsidies and regulations. For example, the European Union’s Directive 2002/96/EC mandates producers and retailers to offer free systems for returning waste electrical and electronic equipment. EU Member States must collect at least 4 kg per person annually, while producers must ensure 50-80 per cent of collected appliances, by weight, are reused or recycled, depending on the product type. Manufacturers also bear the costs of collection, treatment, recovery, and eco-friendly disposal.

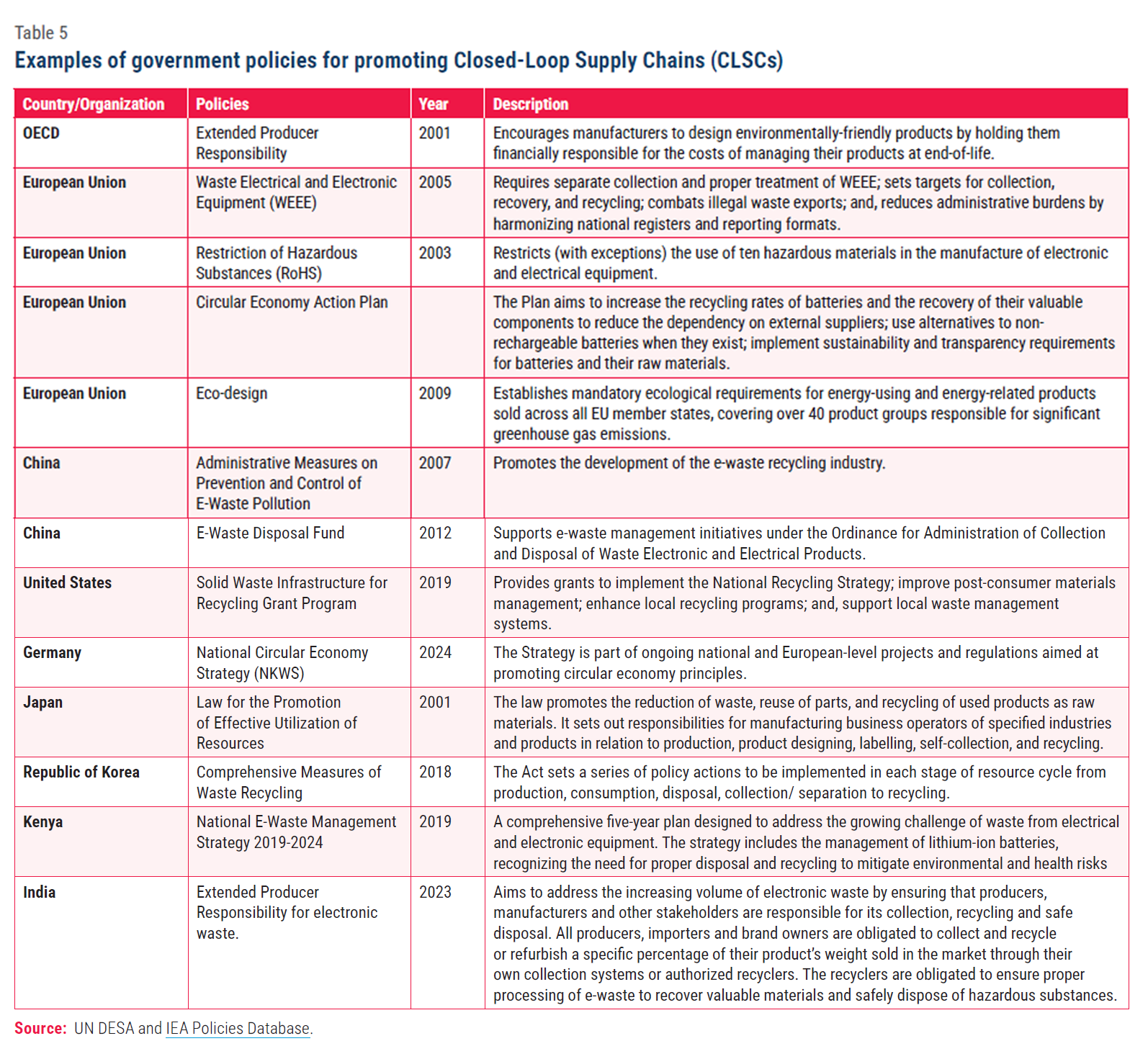

Over time, technologies and management practices have evolved to address the challenges of resource efficiency and waste management. Moreover, various policies have been enacted to enforce the adoption of CLSCs, with a growing emphasis not only on reducing the production cost but also on unlocking additional revenue through innovative recycling and resource recovery practices, such as the European Union’s Waste Electrical and Electronic Equipment (WEEE) Directive in 2005. Table 5 presents some examples of such policies. The United Nations Agenda 21, adopted at the 1992 Earth Summit, highlighted the necessity of responsible production and consumption as critical elements of sustainable development, which also aligns with the objectives of CLSCs.

Over time, technologies and management practices have evolved to address the challenges of resource efficiency and waste management. Moreover, various policies have been enacted to enforce the adoption of CLSCs, with a growing emphasis not only on reducing the production cost but also on unlocking additional revenue through innovative recycling and resource recovery practices, such as the European Union’s Waste Electrical and Electronic Equipment (WEEE) Directive in 2005. Table 5 presents some examples of such policies. The United Nations Agenda 21, adopted at the 1992 Earth Summit, highlighted the necessity of responsible production and consumption as critical elements of sustainable development, which also aligns with the objectives of CLSCs.

Policy recommendations for unlocking recycling potential for critical minerals

While policy ambitions around recycling continue to grow, significant potential remains untapped in recycling from waste and scrap materials, which could help meet the rising demand for these resources. Expanding policies that encourage recycling efforts would not only reduce reliance on imports but also help mitigate the risk of future supply disruptions. To fully harness this potential, a comprehensive and strategic approach is essential.

The following recommendations are categorized by implementation level.

National Level Priorities

- Build Local Capacity and Infrastructure. Workforce training programmes should focus on equipping individuals with skills in advanced recycling technologies, such as hydrometallurgy and bioleaching, enabling efficient recovery of critical materials. Local recycling hubs tailored to manage electronic waste, batteries, and industrial scrap, like modular recycling units deployed in Ghana, can foster domestic industries and create job opportunities. These modular units are effective in minimizing transportation costs and addressing regional waste management needs.

- Promote Technological Innovation. National innovation funds should support the localization and scaling of advanced recycling technologies to suit regional constraints. For example, hydrometallurgy and bioleaching processes that have proven effective in extracting valuable minerals with lower energy consumption can be tailored to local contexts. Governments should also launch R&D programs to improve recycling efficiency and offer tax breaks, grants, and subsidies to incentivize private sector investment.

- Adopt Economic and Regulatory Safeguards. Mandatory recycling targets and Extended Producer Responsibility (EPR) policies should require producers to finance the end-of-life management of their products, similar to frameworks in the EU and India. Environmental standards must ensure the use of cleaner technologies, while price stabilization mechanisms, such as strategic stockpiling, can mitigate market volatility. These safeguards provide predictability for investors and ensure alignment with sustainability goals.

- Foster Material Substitution. Investment in alternative materials, such as sodium-ion batteries or bio-based composites, should be prioritized. For instance, targeted research grants and industry partnerships can accelerate the commercialization of sodium-ion batteries, reducing reliance on critical minerals like lithium and cobalt.

Regional Level Priorities

- Develop Regional Innovation Hubs. Centers of excellence can drive research, development, and dissemination of recycling technologies tailored to local challenges. For example, such hubs could adapt modular recycling technologies like those successfully implemented in Ghana to other regions, enabling countries to maximize material recovery while minimizing costs and environmental impacts.

- Harmonize Regional Regulations. Recycling standards and waste management protocols should be aligned across borders to streamline the trade of recyclable materials. Many foreign investments are being reshored to countries with more relaxed environmental laws with respect to waste management. These investments can add to the existing environmental challenges in the host countries. To avoid a race to the bottom, regional standards and environmental laws can be developed along with regional innovation hubs.

- Encourage Regional Cooperation. Sharing successful models, such as Japan’s urban mining systems or the EU’s Battery Directive, can inspire actionable reforms in neighboring countries. Regional platforms should promote the exchange of knowledge, best practices, and technical expertise. By aligning regional priorities, countries can maximize the efficiency of shared resources and accelerate the transition to sustainable recycling practices.

International Level Priorities

- Expand Global Standards and Frameworks. International guidelines for critical mineral recycling should be expanded under agreements like the Basel Convention to include comprehensive standards for waste processing and trade. These frameworks should also address equitable access to recycling technologies for resource-constrained nations.

- Facilitate Technology Transfer. Affordable licensing agreements for patented recycling technologies must be prioritized to enable wider adoption, especially in developing countries. For example, technology transfer initiatives modeled after successful pharmaceutical access programs can ensure the availability of modular recycling systems and advanced recovery methods in resource-constrained regions. There is a need for revisiting the TRIPS Agreement at the WTO to facilitate green technology transfers with advance flexibilities.

- Support Collaborative Funding Mechanisms. Development banks and climate finance initiatives should fund recycling infrastructure and capacity-building projects in developing nations. Equitable access to funding is critical to ensure participation from all countries, particularly those with limited resources.

Promote Open Innovation Platforms. Shared intellectual property initiatives can democratize access to cutting-edge recycling technologies. Open innovation platforms should focus on advancing low-energy recovery methods and improving sorting technologies. For example, shared research networks can prioritize innovations in hydrometallurgy and bioleaching to make these processes accessible and cost-effective for developing regions. - Strengthen International Knowledge Exchange. Best practices, such as Japan’s urban mining initiatives and modular recycling units in Ghana, should be shared globally to inspire actionable reforms. Collaborative international projects can pilot innovative recycling technologies and scale effective models for wider application. Funding mechanisms like those supported by development banks and international organizations should back these efforts to ensure equitable access and widespread adoption.

Conclusion

The transition to sustainable critical mineral supply chains is vital for advancing the global energy transition. Linear supply chains, reliant on finite resource extraction, are not only unsustainable but also exacerbate geopolitical, economic, and environmental vulnerabilities. Our estimates show that many countries, both developed and developing, have considerable potential to recover critical minerals from recycling waste and scrap. Recycling and closed-loop supply chains can minimize the ecological harm that comes from mining and primary extraction of critical minerals globally, while also reducing dependency on imports. Such capacities will become increasingly important as the green transition advances and can be critical in supporting broader sustainability objectives.

To realize this potential, technological innovation must be prioritized. Proven recycling methods, such as hydrometallurgy and modular recycling units, need to be scaled and adapted to regional contexts. Governments should foster innovation through targeted investments in research and development, coupled with economic incentives to attract private sector participation. Establishing local capacity and regional innovation hubs will ensure that countries, particularly developing ones, can integrate into global supply chains and reap the economic benefits of recycling.

Strong regulatory frameworks are critical to promote responsible recycling, enforce environmental standards, and ensure fair distribution of economic benefits. International collaboration, including technology transfer and the adoption of affordable patents for environmentally friendly technologies can bridge gaps in access and capacity, fostering global equity in critical mineral management.

The path forward requires coordinated action, leveraging technology, policy, and international cooperation to transition toward circular economies. By addressing these challenges, nations can secure the critical minerals needed for the green transition while supporting sustainable growth and resilience.

Welcome to the United Nations

Welcome to the United Nations